REAP-Canada is an independent research and educational organization that is finding ecological solutions to energy, fibre and food production challenges. It is a partner in the Eastern Ontario Model Forest and is assisting farmers in the development of biomass energy production and utilization systems.

REAP-Canada, Box 125, Ste-Anne-de-Bellevue, QC H9X 3V9 Tel: (514) 398-7743 Fax: (514) 398-7972 Eastern Ontario Model Forest, P.O. Bag 2111, Kemptville, ON KOG IJO Tel: (613) 258-8241Preparation of the first draft of this report was financed by Natural Resources Canada. Subsequent revision and publication was financed by REAP - CANADA, under contract to Natural Resources Canada's Model Forest Program.

The assistance of several reviewers is gratefully acknowledged. Among these are Bob Bourchier, Ron Braaten, Peter Cheeseman, Norm Hudson, Charles LeMay, Jeff Monti, Ted Owens, Stelios Pnevmaticos, Jim Richard, and Tony Short.

Canada now spends over $6.5 billion annually to import oil while one and a half million Canadians are out of work. All the while, the country's forest biomass is largely ignored as an enormous and untapped resource of domestic energy supply and regional job creation.

Imported oil is still cheap at $17-20 per barrel. But this is the dockside price; at Armstrong, Ontario, north of Lake Superior, the cost of oil for school heating is $0.50 per litre, or $80 per barrel. The town, however, is surrounded by hundreds of square miles of forest containing large quantities of biomass ready to harvest. With a high unemployment rate, there is no shortage of manpower with which to undertake the harvest. Thanks to local initiative, the new school is now heated by woodchips. Although the capital cost of the chip-fired system was higher than oil system, the long-term costs will be much lower; in addition, local employment has increased and financial resources stay in the community.

In many communities in which the local economy is sawmill-based, wood residues are a disposal problem. In many communities that depend on forest products, supplies of merchantable timber are running out. Intensive management of the cutover areas close to these towns is the only hope for the future, even though the cost of removing junkwood from this land and restoring its productivity can be formidable. But if this junkwood can be chipped and sold as fuel, the economics are greatly improved, a route that several European countries have already started to take.

Potential markets for chip-fired thermal energy include the small-commercial sector (greenhouses, motels, highway maintenance garages, nursing homes, factories, hockey arenas), and the institutional sector. Another major market is the heating of farm complexes, with a single boiler heating the house, barn workshop, etc. There are more than 60 such installations in PEI already. From an environmental perspective, chip combustion has much in its favour relative to burning high sulphur coal or operating a nuclear facility.

The potential contribution of woodchip combustion is largely unrecognized within the Canadian social and economic infrastructure, and requires government initiative and leadership in order for the long-term benefits to materialize.

Woodchip combustion is a potential energy source of great significance for Canadian society in the twenty-first century. Not in big cities, not for powering airplanes, but for providing both process and space heat at lower cost to thousands of small-commercial operations, factories and farm complexes. Woodchip combustion holds great promise for the provision of space heat to hundreds of schools and institutions in the future. As a bonus, this energy source could also generate thousands of jobs on a local basis and reduce the drain of cash needed to purchase imported oil. In the short-term, the jobs generated by the establishment of woodchip combustion systems and infrastructure may be more important to Canada than the energy itself.

This report will focus on the economic and social context in which woodchip combustion systems will operate, will identify the major problems facing the widespread adoption of such systems, and will analyze an option which could have a role in reducing the impact of these barriers.

The social and economic context can be summarized as follows:

Canadian petroleum imports have risen rapidly, from $0.6 billion in 1970 ($1.9 billion in 1990 dollars) to $6.5 billion in 1990 (11). While Canada has also been a traditional exporter of heavy oil, which offsets the value of the light oil imports, the country is losing ground. Canada is destined to become a net oil importer with present economically exploitable reserves, further weakening the trade balance. Oil production in the USA, USSR and the North Sea is also dropping due to resource depletion, and OPEC's share of world oil production is rising steadily.

2. Human Resource

Canadian unemployment is above 11%, not including the withdrawal of hundreds of thousands of persons from the labour market. The highest unemployment rates often occur in small communities surrounded by forest, and the majority of these communities do not have access to natural gas.

3. Overall Cost

Although the capital costs of biomass-fired heating systems can be considerably higher than for oil-fired systems, the operating costs are much lower, which permits amortization of the additional capital cost and a net saving. More employment can be generated by biomass combustion and, unlike oil combustion, almost all the operating money spent on biomass combustion remains within the local economy.

At current world crude oil prices, about US$1619 per barrel, biomass is usually not competitive for installations below 200 kW (700,000 BTU/h), approximately the peak demand for a 10-room school. However, this figure is only a generalization, and relates to installations using relatively high cost purchased chips. There are many variables to be considered. The relative costs of oil and biomass vary widely, as do climate and insulation standards. In PEI, school boards pay 21 cents/litre for oil ($33/barrel) and $32 per green tonne of fuel chips. In Peterborough, Chapleau and Dryden, Ontario, the school cost of oil is 25.8, 26.2, and 27.5 cents/litre respectively. In Armstrong, Ontario (250 miles north of Lake Superior) fuel costs are 50 cents per litre ($80/barrel) for oil and about $33/tonne for purchased chips. The delivered cost of oil at a satellite school near Armstrong is $1.04/litre.

The delivered cost of chips varies appreciably according to the scale of the operation, the volume of fuel-quality wood per hectare, the quality and spacing of access roads, distance to market, and other factors (5,6). Typical costs range from $23-$26 per green tonne for large operations, to $28-$32 per green tonne for small operations.

The use of relatively cheap biomass fuel can have advantages in addition to cost saving. For example, pig farrowing barns in PEI are heated by hot water circulated in pipes imbedded in the concrete floor. Because the floor is warm, the piglets do not have to struggle to get close to the sow, and time to market is reduced from 160 to 142 days. Because the heat is cheap, the rate of air change is increased, and health problems decrease. In an autobody shop with floor heating, there is less dust in the air, and labour productivity is increased.

Public sector investment is usually determined by immediate capital cost, not by long-term costs. Since biomass combustion involves higher capital costs, it is usually dismissed as an option. The opportunity for lower long-term costs to the taxpayer, and the opportunity to generate local employment, are both ignored. The fact that the conversion efficiency of gas and oil-burning appliances is higher than that of wood-burning appliances also seems to act as a barrier.

The establishment of a chip supply infrastructure in a community is facilitated if a school or hospital provides a steady minimum demand for chips. The heating system can be either new or retrofit; the latter usually offers a faster payback. This means that government initiative is essential if there is no local supply of mill residues. In the long-term, however, government expenditures are reduced, quite aside from the resulting social benefits. Subsequent installations can include a variety of commercial operations such as greenhouses, pig farrowing operations, small forest products plants, apartments, motels, etc. Chip combustion in single family dwellings will seldom be economic while the price of oil is low. However, there is a 30 kW (100,000 BTU/h) Finnish chip stoker that is highly efficient, and three are now operating in Canada.

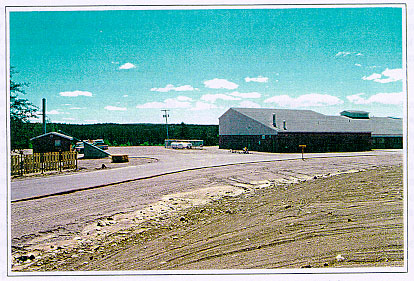

New school at Armstrong, Ontario, with chip-fired boilerhouse on the left.

photo: Sylva Energy Systems

It appears that biomass combustion in modern appliances can meet any reasonable emissions standard, and indeed offers some environmental benefits compared to conventional fuels. The subject of atmospheric pollution will be further discussed later in this report.

Many Canadians are concerned with the condition of their country's forest resources which, particularly in Eastern Canada, have been heavily exploited over the past 100 years. Removal of choice trees has left forests with only undesirable species and interior specimens of desirable species. Woodchip production could provide a market for this junkwood1 providing an income to partially offset the cost of intensive forest management which, in turn, would increase the quality of the timber supply. This is exactly what several European countries, including Sweden and Austria, are doing.

In 1991, total Canadian primary energy demand was approximately 8.03 x 109 GJ (8026 PJ)2. and, of this, approximately two-thirds was for space and process heat (3). Current residential wood consumption is estimated to be 110 PJ. (1). The forest products industry provides about 500 PJ - 350 PJ from combustion of black liquor (a pulping by-product) and 150 PJ from combustion of mill residues. Another 150 PJ is available from mill residues not currently utilized (often due to transport costs). The allowable cut of junkwood forest is unknown; it is vast, although much of it is not economically available. However, since $6.0 billion in oil imports is approximately equivalent to 1800 PJ, it is obvious that woodchip combustion can only replace a modest portion of the imported oil.

This report is aimed at those who can initiate and support conversion from oil combustion (or electrical heating) to biomass combustion in the institutional and small-commercial sectors, and to those designing new installations. These include provincial government officials, institutional officials such as school boards, business leaders from the small-commercial sector, and farmers who have access to low cost wood. The economic and social potential of such conversion in Eastern Canada is examined, but much of the message is relevant to other parts of Canada, especially those without access to natural gas.

The report contains technical information concerning wood chip combustion, to give a better understanding of the options available. Since woodchip combustion in Canada is only in its infancy, much of the information is based on observation and informal communication rather than on detailed studies. There is a need for studies, particularly in relation to emissions and to employment generation, but this should not be used as an excuse to delay development of a woodchip combustion industry.

Large systems used for hospitals and large schools, and small systems used for some schools, greenhouses, motels, and farm complexes have the same basic components for:

(i) receiving chips

(ii) storing chips until they are required

(iii) moving the chips to a combustion chamber when there is a demand for heat

(iv) combustion of the chips to produce hot gases

(v) circulating the hot gases through a heat exchanger where the heat is transferred to the circulating medium (usually water or oil, or air in very small installations)

(vi) venting the waste gases

(vii) delivering the heat to the desired location(s)

In addition, larger systems have provision for automatic ash removal. Most woodchip combustion systems incorporate an oil or gas-fired backup combustor; in some cases an electric boiler is installed for emergency use.

While control systems vary according to the size and sophistication of the appliance, they are relatively simple. Large installations often use variable-rate feed systems which can be geared down to almost imperceptible movement when demand is low. In most small installations the feed switches on and off, and it is usually necessary to stop the feed auger completely when demand is low. Either a timer is used to feed a very small quantity of chips periodically onto the grate in order to "hold fire", or an automatic ignition system is used to restart combustion.

An important variable relating to plant reliability is chip quality. This concerns mainly physical uniformity; long splinters and excessive fines should be avoided. A lot also depends on the fuel moisture content; wet fuel at a low feed rate may be unsatisfactory. Nevertheless, some appliances can handle a motley mixture of hogged residue without difficulty. To be safe, the proposed fuel should be test fired in an existing installation. Fuel cleanliness is also important; sand and gravel will rapidly degrade the equipment.

Most chips are produced by chipping whole low-quality trees or by chipping residue containing bark, and thus contain perhaps 15% bark. Sometimes bark-free, pulp-quality chips are burned because there is insufficient market for pulp chips.

Since "overall efficiency"3 is greatly affected by fuel moisture content, the Canadian Standards Association performance standard for wood-burning appliances requires that the lumber used as test fuel be at 18% MCwb4.

A typical institutional combustion system is provided by Sylva Energy Systems5 of Thunder Bay, Ontario (Figure 3). The majority are in the 0.5 to 3.0 MW thermal range (1.7 to 10.4 million BTU/h), but some newer ones are rated at 146 kW (500,000 BTU/h). Approximately 95 % of total equipment cost in these installations is for components made in Canada. These systems are designed to burn chips at 50% MCwb, i.e. freshly cut in the forest. However, efficiency is improved if either the roundwood or the chips have dried to 40% MCwb. Ten similar systems have been installed in the U.S.A. over the past 12 years.

In the small-commercial range, 75 to 300 kW (250,000 to one million BTU/h), a typical chip-fired appliance is the Bioblast combustor, manufactured in various sizes by Grove Wood Heat Inc. in PEI and in Ontario (2). The stoker component feeds chips to a grate in a ceramic combustion chamber where hot gases are generated and combusted; from there, the hot flue gases travel through a short tunnel to a separate heat exchanger (Figure 1).

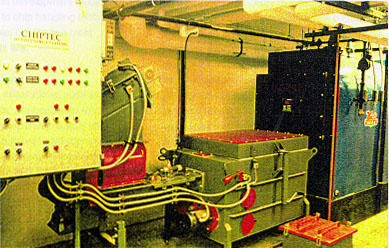

The Bioblast furnace is usually designed for a chip moisture content of between 40% and 35% (wet basis). Chips should be neither dripping wet nor too dry. In the first case, the chips may freeze into large clumps before they reach the appliance, a lot of heat is wasted in evaporating moisture and, at a low bum rate, the fire may go out; in the second case, excessive heat may damage the equipment, and the danger of burnback in the feed auger is increased. However, the appliance, and particularly the relationship between the grate and the incoming chips, can be designed for either wetter or dryer fuel. A somewhat similar combustor, with less provision for pre-heated air, is manufactured in Vermont; it is a combustion gasifier called the ChipTec, not to be confused with a typical European engine-fueling gasifier.

A variety of heat exchangers have been coupled with the Bioblast; an example is a 130 kW (444,000 BTU/h) vertical-fire-tube boiler manufactured by Parrsboro Metal Fabricators in N.S. (Figure 2). Based on the Canadian Standards Association standard for performance testing (B415), overall efficiency for the system is about 72% over most of its output range. A number of vertical-fire-tube boilers have been designed and fabricated recently in PEI. However, many Bioblasts have been coupled with used and inexpensive horizontal-tube boilers.

The following examination deals primarily with chip-fired systems. However, there is another widely used, slightly less expensive, biomass fuel called "hogged fuel". This is wood, usually sawmill residue, which is smashed into bits of widely varying sizes by flailing hammers rather than into relatively uniform chips. In PEI hogged fuel is not available whereas, in New Brunswick, it is widely used. The combustion equipment Involved is almost identical.

It is necessary to distinguish between the two types of large, biomass-fired, power-generating plants, i.e. electricity generators, and thermal power generators. A plant producing 25 MW of electrical energy requires approximately the same fuel input as a plant producing 75 MW of thermal energy. Ordinarily, the former provides only a small amount of thermal power.

PEI has by far the most chip-fired installations, for three reasons. Firstly, the province has high electricity rates, about 11 cents per kWh, much higher than Nova Scotia or New Brunswick; secondly, the federal government financed a major program in that province to promote woodchip combustion in both small and large installations; and thirdly, the Bioblast is produced there. On the other hand, many communities in northern Ontario have off-grid electricity costs in excess of 50 cents per kWh but there is hardly a small-commercial chip combustion installation in sight.

The PEI institutional installations include six hospitals, eight schools and a prison. The last six school installations have similar 450 kW (1.5 MBTU/h) Sylva Energy System boilers, each capable of burning about 525 green tonnes of chips and displacing about 115,000 litres of oil annually. There are about 60 Bioblast installations, mostly in the 90 - 150 kW (300,000 to 500,000 BTU/h) range. Most are installed on farm complexes where they heat some combination of pig farrowing barn, poultry barn, machine shed, house, etc. The commercial installations include greenhouses, a fish hatchery, nursing home, highway equipment garage, motels, and a machine shop.

In addition, PEI pioneered chip-fired district heating in Canada. This concept, developed in Sweden, involves a central heating plant and kilometres of insulated pipe, buried a metro deep, carrying hot water to hundreds of homes and businesses and large office buildings. The first Charlottetown hearing loop has a load of 1.8 MW (6.1 MBTU/h); the second loop has a current load of 13.7 MW. Each building has its own heat exchanger so that the building's internal hydronic system can operate at a lower pressure than the district system, and be serviced without interfering with the latter. An additional 15 MW wood-fired plant and a 15 MW oil-fired plant are planned for construction soon to expand the district heating system. There are two such systems in the U.S.A.

In Newfoundland the largest installation is a 5 MW electrical generating plant. There are also three hospitals and a scattering of smaller chip-fired installations.

In Nova Scotia the largest operation is a 2.5 MW thermal (8.5 MBTU/h) textile factory system which has been run on both chips and hogged fuel. There are also two hospitals, an agricultural college, a large pig farrowing operation, a poultry processing plant, and a huge greenhouse with a 30 MW (100 MBTU/h) system which originally ran on hogged fuel but later switched to chips.

In New Brunswick there is a 12 MW thermal (41 MBTU/h) district heating installation at the University of New Brunswick which supplies a large hospital, two university campuses, an apartment building, and several industrial buildings. It burns a screened mixture of hogged fuel and conventional chips. There are at least 14 hospitals and one large school using hogged fuel with a high sawdust content and some chips. Construction is expected soon of two 25 MW electricity-generating, biomass-fired plants near Sussex and Kedgewick, although electricity buy-back rates from New Brunswick Power are low. Each plant will require 300,000 green tonnes of biomass annually, 80% sawmill residue and 20% whole tree chips. Negotiations are on-going for a 58 MW electrical, co-generation plant 6 associated with a forest products complex in Edmunston, which will sell the electricity.

Possibly due to low hydro rates, there are few chip-fired systems in Quebec; there is one ChipTec gasifier in a lumber drying operation north of Montreal. Many forest products plants burn hogged residue.

In Ontario, a college near Brockville operates a 1.5 MW (5 MBTU/h) plant burning chips and other biomass. Two secondary schools operate on hogged fuel. The Petawawa National Forestry Institute has a 0.67 MW chip-fired boiler and a new school north of Lake Superior has a 0.38 MW boiler. There are also a few greenhouse, farm, garage and cabinet shop installations.

To develop the technology and expertise required for widespread use of hogged wood residues for power generation, to reduce the flow into landfill sites, and to ease the demand on Ontario Hydro, the Ontario and federal governments subsidized the construction of three co-generation plants adjacent to sawmills. The emphasis was on electricity generation. The first, built in Chapleau in 1987, is entirely residue-fired and is rated at 7 MW. Due to its small size and the relatively low hydro buy-back rate, this operation has not been a financial success. The second, built in Cochrane in 1989, produces 27 MW of electricity from natural gas and 10 MW from combustion of wood waste, in addition to 6 MW of steam and hot water for the adjacent sawmill and plywood plants. The third, built in 1991 in Kirkland Lake, produces 66 MW of electricity from natural gas turbine generators and 36 MW from steam turbine generators powered by wood-residue-fired boilers plus the gas turbine exhaust steam.

There is a small Sylva combustion system in a new school (27,000 sq. ft.) in Armstrong, north of Lake Superior, where oil costs 50 cents/litre ($80/barrel), the supply of low quality wood is virtually limitless, and unemployment is high. Electricity costs 57 cents/kWh!

The installation blends well with the surrounding buildings (see photo). One man has a contract to provide the chips, and maintain both the boiler house and school. He uses a whole tree chipper to process spruce and poplar.

The school board wanted to design for a maximum load of 193 kW (660,000 BTU/h); consultants hired by the province decreed that a capacity of 380 kW (1.3 MBTU/h) was necessary; in fact the actual maximum demand is about 110 kW (375,000 BTU/h), which means that a smaller, much less expensive system would have satisfied the building's requirements. Several schools in Vermont are heated by systems that are comparatively compact (see photos). The Board under-estimated combustion system efficiency and building insulation effectiveness. Some of the surplus capacity will be used for a teachers' residence and melting ice on driveways, but the over-all excess has meant unnecessary capital cost and continuing extra operating costs.

During installation start-up it became evident that the key to operating far below capacity is to gear down the feed system so that the fuel keeps moving, even if motion is imperceptible. The system layout is shown in Figure 3. It consists of an in-ground chip storage bin; hydraulically-powered fuel rakes to move the chips to the horizontal screw conveyor which feeds the bucket elevator; a stoker bin which feeds chips into the combustion call; a 3-pass fire-tube boiler (heat exchanger); a fly ash precipitator; and a vent. The return water line passes through the propane-fired back-up boiler.

Operating costs for the chip-fired system are 65% less than the estimated costs for an oil-fired system. This ties in closely with estimated reductions of 33 to 67% for schools in PEI. Approximate 1990 capital cost for the 380 kW installation was $270,000, including $100,000 for the in-ground chip storage bunker. It is designed to hold 17 tonnes of green chips. The estimated annual consumption is 200 green tonnes, and in -40ºC weather the system burns about 1.4 tonnes/day.

Due to the success of this installation, several other installations are in place or under construction in the Armstrong area. Due to the high cost of purchased electricity, the feasibility of installing either a packaged 35 kW steam turbine generating plant or an engine-fuelling gasifier is being investigated.

Most Bioblast furnaces have been installed in PEI farm complexes and have involved new Bioblast combustion cells and simple fuel handling systems (Figure 1). These installations have proved successful, and are increasing at an average rate of 12 per year. The prime incentive has been the availability of low cost fuel, either sawdust, shavings and chips from sawmills and small forest products operations, or chips from low-grade trees growing on the farm. In some areas a chipper and experienced operator/maintenance man can be rented. In others, farmers have purchased tractor-mounted chippers or they simply haul chips from a sawmill or hogged fuel from a wood processing plant. Since space is cheap on a farm, and dry fuel is usually unavailable in the winter, most operators acquire a full winter's supply of fuel in the fall, and store it in a pole-type shed close to the boiler house (see photos on page 14).

One PEI installation involves a large pig farrowing barn plus the farm house and machine shed (8). The shed, formerly a potato warehouse, contains the 120 kW Bioblast, a non-pressurized 150 kW Bioblast (Maco) boiler, a workshop, and fuel storage area. The boiler is connected to a 500-gallon thermal storage tank which acts as a heat dump in the event of a heat build-up in the boiler due, for example, to a power failure. (It could also serve to satisfy a sudden heavy demand for heat.) From there the hot water is circulated to an oil-fired back-up boiler in the sow barn via insulated 1-¾ inch diameter underground steel pipes which are encased in styrofoam. A separate line delivers hot water to the house where a water-to-air heat exchanger connects to the hot air heating system of the house. A water-to-water heat exchanger is used to provide domestic hot water. The boiler has a separate door which can receive roundwood (if the chip system is out of commission for any reason) and dead pigs. This capability is essential because any dead pigs must be cremated.

The fuel is a variable mixture of sawdust (70%) and shavings (30% maximum) which costs only $6.50 per tonne at the sawmill. The owner uses his own tractor trailer to haul it to the farm where it is dumped on the ground and moved inside the storage building with the tractor loader. An old skid-steer loader is used to transfer the fuel from the storage pile to the Bioblast hopper twice daily. Some fuel has been wet, 48% MCwb, but it did not cause problems, probably because the combustor ran steadily at high fire. Ash is removed manually from the grate each day. Several stoppages occurred when pieces of wood in the sawmill residue jammed the feed auger and broke the shear pin.

Table I - Approximate 1988 capital costs of PEI Bioblast Installation

|

Skid-steer loader |

$ 2000 |

|

Bioblast hopper plus combustor |

6000 |

|

Bioblast (Maco) boiler |

6000 |

|

Vent (chimney) |

500 |

|

Piping and plumbing (including labour) |

3500 |

|

Total |

$ 18,000 |

The relationship between maximum demand and annual consumption depends on many factors. A plant with a year-round demand for process heat will use far more fuel than a plant used only for space heating. Also, after conversion to chip heating, some buildings are probably kept warmer than they were before. The data are not available to provide a reliable estimate of chip consumption for each end user, but the following indicates the type of calculation required.

In the case of installations now heated by roundwood, it is probably safe to assume that wood consumption will be halved by conversion to chips, i.e. a farm using 80 cords of roundwood would need to chip only 40 cords. The reduction is due more to the improved combustion control in the chip-fired system than to the modest improvement (perhaps from 50% to 60%) in combustion efficiency.

A farmer can compare demand to that of other farms already using roundwood, or can make an estimate based on oil consumption. If oil consumption is 16,000 L, and a litre provides 29,360 MTU of delivered heat, then annual BTU demand is 16,000 x 29,360 = 470 MBTU.

If oil consumption for this example is 16,000 L/ yr, and the average efficiency of the combustor over a full year is likely to be 60%, then hardwood chip consumption can be calculated as follows:

1 litre #2 fuel oil = 36,700 BTU

If fuel oil combustor has 80% efficiency, 1 litre yields 29,360 BTU

Then 1 tonne chips would displace 5.9M/29,360 = 200 litres of oil

1 green tonne chips = 9.8 MBTU

If wood chip combustor has 60% efficiency

Therefore, the farm would require 16,000/200 = 80 green tonnes of chips = 40 cords of wood

Annual chip consumption is affected by average overall efficiency, which in turn is affected by average load. Combustion efficiency decreases as demand falls below the optimum operating range of approximately 75 percent. In several applications in PEI, two systems have been established in parallel (eg. 2 x 150 kw systems = 300 kw) to overcome this problem. The merits of this approach are described by McCallum (9):

Bobcat loading woodchips into furnace hopper, (courtesy of Grove Wood Heat)

In some instances it may be preferable to install two small biomass burners rather than one large burner. This will allow the operator to run one burner with a good load during periods of low demand, for example, during the spring and fall shoulder periods, and bring on the second burner for periods of high heat demand. Where the heat load varies significantly a two burner system can achieve a much higher efficiency than systems with one large burner. In addition, if one burner breaks down you are not left without any heat or forced to switch completely to burning often. One must compare the relative costs of two smaller burners versus one larger one in terms of capital cost, average combustion efficiency and the percentage of oil consumption that can be displaced. When you are installing only one biomass unit the rated capacity of that burner should be equal to 50-70% of the capacity that is known to be adequate to meet the peak heat demand. This will allow the biomass system to carry the base load and the oil system to pick up the peak demand on the coldest days of the heating season. A biomass burner rated at about 60% of the Peak can typically displace about 80% of the total historical oil consumption. A two burner system can be sized to meet the peak heat demand and it may allow displacement of dose to 100% of oil consumption.

Significant volumes of fibre quality, low-grade forest products are available close to many communities. Current markets are inadequate to fully utilize this low-grade material, inhibiting the forest manager's ability to carry out good management practices. Available fibre quality material includes - early plantation thinnings; - thinnings from hardwood improvement cuts; - undesirable species, defective trees, and tops not utilized in current harvesting operations; - sawmill residues - bark, stabs and chips.

The inability to conduct properly timed thinnings reduces the economic potential of many forest stands. Providing markets for these products will enhance management techniques, increase the available wood supply from the forest, increase the supply of high quality sawlogs and veneer, as well as increase the overall economic benefits from the forest. Local markets for biomass fuel consumption are desirable from a forest management standpoint as they utilize a wide range of forest species, tree sizes (length and diameter) and can be economically viable on a small scale.

C02 production and the "greenhouse effect" are important to everyone. Provided that junkwood is replaced by new forest, wood combustion makes no net contribution to C02 in the atmosphere. On the other hand, oil, coal and natural gas combustion release carbon that was taken out of circulation millions of years ago.

Wood normally contains little sulphur and its combustion generates only minute amounts of nitrogen oxides; therefore, in general, wood combustion does not contribute to acid rain.

Fuel chips often contain fungi, and some persons are allergic to the spores which are released as the chips dry. Therefore a draft of air from the drying chips should never be allowed to circulate into living quarters.

Regulatory Problems

Some provinces are considering regulations to prohibit the sale of residential wood-heating appliances that do not satisfy Canadian standards for wood combustor performance such as CAN/ CSA-B415.1-M92, the standard for wood-fired stoves. This standard includes determination of both emissions and efficiency. The emissions limits are identical to the U.S. Environmental Protection Agency (EPA) regulations relating to emissions from small and medium-sized wood stoves, but the Canadian standard also includes emissions from large stoves. Particulate emissions from stoves must be approximately one-tenth (or less) of the average emissions 15 years ago. A standard (B415.2) for central heating installations up to 1500 kW (5.1 MBTU/h) is in preparation.

Unfortunately, provincial particulate emission guidelines for the small-commercial range, 60 to 1500 kW (205,000 to 5.1 million BTU/h) are in a state of confusion. Some jurisdictions have limits that were based on large co-generation plants cleaner, in terms of grams of particulates per megajoule of energy input, than EPA-certified stoves

These regulatory difficulties are compounded because Environment Canada emissions regulations for combustion appliances (which relate to all installations which involve some federal financing) were designed to deal with the combustion of municipal solid waste but they do not specifically exclude combustion of wood waste. Huge municipal installations can achieve far lower emissions than can be achieved economically in small wood-fired installations. However, chip-fired systems simply do not generate the wide variety of toxic gases that may be expected from municipal solid waste. It is worth noting that the area of productive forest land burned by wildfire each year is approximately 50% greater than the area harvested for all products (7).

Combustion emissions are a major concern to most Canadian governments and individuals but there is no comprehensive report available to put wood combustion emissions into perspective with emissions from oil-burning appliances, coal-generated electricity, coal-fired systems for space and process heat, and other pollution sources such as automobiles. A federal-provincial task force is currently working on this problem in relation to large systems, 10,000 kW and up, but a similar study is still needed in relation to the small-commercial sector. Lack of comprehensive information on this subject is acting as an impediment to the development of wood chip combustion.

All forms of combustion have environmental implications, but chip-fired appliances have many advantages in comparison to traditional energy sources.

Canada cannot afford to continue to import oil, even at today's prices. That money could be better used to import high technology products that cannot be produced economically. In 1992 the non-merchandise trade deficit was $38.1 billion, the merchandise trade surplus was $9.5 billion, leaving a shortfall of $28.6 billion which must be borrowed. It would be a major stop in the right direction if oil imports could be cut by $1 billion annually.

The survival of small communities in forested areas will be dependent on the development of sustainable alternatives to present economic activities. Money spent on biomass fuel stays in the community, and the cost of heating small-commercial establishments and schools is decreased. Employment is generated in these traditional areas of high unemployment. It would be better to use tax dollars to pay local labour to produce fuel chips than to hand it out through social assistance programs.

The production, delivery and combustion of fuel chips from any source creates more local employment than heating with oil or electricity, but the extent of the increase depends on the way in which the chips are produced. Chipping sawmill residue involves little additional labour at the sawmill; in fact, it solves a disposal problem. Clear-cutting and chipping a junkwood forest involves an appreciable forestry operation. Intensive forest management involves thinning and culling a forest removing a reduced volume per tonne of chips produced. There are now sufficient installations in PEI, both farm and small-commercial, to warrant a study of employment generation.

The economic benefits of woodchip-fired electricity generation in New Hampshire have been analyzed through intensive modelling (10). Based on a 1989 output of 150 MW (9.6% of peak demand), the estimated benefits from the electricity sales only (i.e. excluding heat sales) were: 205 full-time direct jobs, with $7.7 million in payroll benefits; 591 indirect jobs; $17.8 million in chip purchases; $1 million in property taxes; 32,532 tons of wood ash for soil enhancement; and total economic benefit to New Hampshire of $260 million.

The use of woodchips for fuel would support the Canadian forest products industry, traditionally Canada's single largest source of foreign exchange and currently the source of one-eighteenth of all direct full-time jobs. The export data (13) for 1990 are shown in Table 2. The data in Table 3 provides an historical perspective of the role of forest products in Canadian external trade.

|

Exports --($billions)-- |

Balance of Trade -- ($billions)-- | |

|

Forest products |

22.1 |

18.8 |

|

Farm |

9.0 |

1.6 |

|

Fish |

2.6 |

1.9 |

|

Energy |

15.2 |

7.4 |

|

Metals and Mining |

20.6 |

9.2 |

|

Other Prod. |

70.3 |

-25.4 |

|

Total |

141.4 |

12.4 |

Table 3 - Forest Products Exports

| 1990 | 1980 | 1970 | 1960 | 1950 | |

| Value $1990 billions | 22.1 | 19.7 | 9.4 | 6.6 | 6.0 |

| % of total | 15.6 | 17.2 | 18.3 | 31.8 | 35.5 |

The recent decrease in the rate of growth of forest products exports Is partially due to near exhaustion of "old growth" timber within economic travel distance of communities and manufacturing facilities.

Productive forest close to an established community has much greater economic value than one located 70 to 100 miles away. Local mills are now drawing supply from up to 100 miles and greater. Markets such as energy generation will result in better forest management and increase volumes of all forest products available closer to the mills. Sweden has created markets for fuel quality wood fibre and it's forest products industry is thriving, obtaining optimum utilization of all products and species. It must be acknowledged, however, that intensive forest management does not automatically accompany fuel chip harvesting, and damage to the residual stand is sometimes increased. On the other hand, fuel-chip harvesting improves the stability of the forest industry and increases the involvement of professional foresters, providing the potential for proper forest management.

Greater attention should be paid to Canada's one resource that most nations cannot duplicate - vast areas of accessible productive forest land suitable for a wide variety of species. Intensive forest management generates high quality timber plus large volumes of fuel chips, and the increase in sales could revitalize the forest products industry.

In parts of Newfoundland there are no trees but vast peat bogs. In some PEI locations farmers buy green sawmill residue for $6.50/tonne at the mill, compared to $30 - $33 for delivered chips. Sawdust and shavings have a low energy density (low BTU value per unit volume), but the price is also low. In much of New Brunswick hogged fuel is both cheaper and more easily accessed than fuel-quality chips, and much cheaper than pulp-quality chips. In some areas sawdust is free for the taking; its use as a fuel eliminates a disposal cost. Green sawdust is combustible provided that it has not been exposed to rain. Sawdust must generally be mixed with coarse residue, so that air can move through the fuel, but there are no hard and fast rules. Chips produced by chipping brush along roads and hydro transmission lines are often available at little cost.

Wood pellets are manufactured in B.C., Saskatchewan, Ontario, Quebec, and New Brunswick, and are imported into several provinces. They have a much higher energy density than chips and are more easily stored and handled, but they cost more per tonne. In some areas the cost of electricity is high, and wood stoves have replaced electricity as the main source of heat. Unfortunately this conversion has been accompanied by a major air pollution problem; also, some homeowners find a wood stove too messy. Pellet stoves offer a solution - extremely low emissions, easy to control the heat output, and almost no mess.

A somewhat more extreme example is the use of kernel corn as a fuel. Corn-fired stoves are widely used, particularly in the western U.S.; it is simply a matter of using the cheapest hydrocarbon available. However, corn culture involves soil depletion, soil and water pollution by nitrate fertilizers, and high water consumption; also, the nitrates may cause stove deterioration.

A promising newcomer on the scene is, "C4 perennial grasses". There has been considerable work in Germany, and some in the U.S., on these high yield grasses to produce fuel briquettes.

Most appliances will handle the fuel they are designed for, plus any fuel that is more refined. For example, a chip combustor will also handle pellets, but a pellet stove will not handle chips. Peat, however, can only be burned efficiently in an appliance designed for peat. The main point is that biomass is available in many forms, and the relative price varies from time to time. The operator must seek out the fuel that will minimize heating cost.

This country has neither oil nor coal reserves within its territory; it must strive to reduce the average cost of energy in order to keep the cost of its products competitive. its most important exports are forest products and this requires an annual harvest of quality timber, which in turn requires widespread implementation of intensive forest management. Forest and mill residues have been a disposal problem and this led to their widespread use as fuel for large thermal and electrical generating stations, as well as a heat source in the small-commercial sector.

Woodchip-fired district heating (DH) is common in Sweden. It involves a large heating plant, ranging from 2 to 28 MW (7 to 95 MBTU/h) which provides hot water heating to virtually all the homes and larger buildings in a community. In 1979 there were only two wood-fired DH plants with a total capacity of 9 MW. In 1984 there were 50 installations with a total capacity of 650 MW. The replacement of oil by municipal waste, wood and peat for district heating is remarkable: in 1970, 14.3 TWh oil was utilized, versus 0.3 for indigenous fuels; in 1988, oil was reduced to 6.9 TWh, and indigenous fuels had risen to 9.0.

The most common Swedish chip-fired installation is the farm complex; many apartment buildings and small businesses are also heated by chips, and most such systems are monitored by a sophisticated alarm system with guaranteed service within two hours if a problem occurs. In the absence of such an alarm system, a back-up oil system is usually installed.

United States

The State of Maine resembles most of Eastern Canada; large areas of forest with patches of arable land and no oil wells. For years Maine's forest products plants burned residues to produce energy, but now the emphasis is on non-utility power producers, i.e. companies that generate and produce electricity that is sold to utility companies for distribution, and who sell heat to other companies. In 1989, there were 31 such installations (12). Of these, one burns peat, four burn municipal waste, and the remaining 26 plants burn wood - either mill residues or whole tree chips. Of these, 31 operating biomass plants, 22 are classified as co-generation and 9 as small power producers. The peat plant, rated at 23 MW, can also operate on chips. Currently 640 MW, or 23 percent, of the state's electrical capacity is provided by wood. Maine's largest electric utility recently asked for tenders on additional power; as a result, a 30 MW biomass plant is under construction, and two more are planned.

Some schools in Vermont have been converted to chip combustion, most from electricity but some from oil (4). The first was in 1985, one in 1987, and one in 1988. Three more conversions, and two new schools with chip systems, went into operation from 1989 to 1992, and more installations are planned. These installations all resulted from decisions made by local taxpayers, not the state government, although the latter has strongly supported the program. The federal Department of the Environment subsidized a portion of the total cost.

Missouri and Arkansas have initiated campaigns to promote installation of sawdust-fired boilers in schools. In the U.S. Southeast (13 states) during 1987, the use of solid mill residues and whole-tree chips as fuel to meet industrial energy needs, generated about 54,000 jobs and $840 million in income (14). The figures include jobs and income created when money, saved through the use of wood fuel, is spent on other products; savings due to having avoided landfill costs are not included.

Woodchip heating installation at a Vermont school. Ten schools have been converted from oil or electricity to wood chip heating. (Courtesy of Chiptec Energy Systems)

In an increasingly competitive environment, Canada continues to degrade its position by importing oil and wasting biomass, both mill residues and junkwood forest. The country is suffering severe unemployment while its forests, traditionally the source of its most valuable exports, have been degraded. Some are being rebuilt through forest management while others have been abandoned as no longer economic in the foreseeable future. The future of the Canadian manufacturing industry is threatened by low production costs in many parts of the world, and since oil is a finite resource, the cost of imported oil is bound to rise. Even if the price of oil does not rise in the near term, biomass combustion is now more economic in many situations, especially considering the fact that the financial investment on biomass energy infrastructure and operation stays within the Canadian economy.

To take advantage of indigenous biomass resources, government initiative and leadership is required. Research and development funding, particularly in relation to chip handling technology, would be desirable, but the two most important requirements are:

Chip-fired institutional installations, such as hospitals and large schools, are needed to form the core market in creating local chip supply infrastructures. These institutional installations would reduce government, i.e. taxpayer, expenditures in the long run. Revision of funding regulations to put the emphasis on long-term cost, rather than immediate capital costs, is the critical action required.

Recognition and support for biomass combustion in environmental regulations is also needed to ensure economic viability. A prerequisite is a comprehensive report putting all the major air pollution sources and energy options into perspective. This report would suggest acceptable emissions limits, per MJ of fuel input, for systems in the 75 to 1500 kW range (255,000 BTU/ h to 5.1 MBTU/h). Quite possibly the report could recommend one level for the 75 to 200 kW range, and a lower level for the 201 to 1500 kW range.

Since the use of chips to heat schools, both new and converted, would give a major impetus to widespread conversion in the forested areas of Ontario and elsewhere, it is essential to briefly examine the obstacles to school conversion.

Grants from the Ministry of Education to the school board for operating costs are based on the number of students, and municipal property taxes for education are based on these provincial grants. Although conversion to chip combustion may reduce annual operating costs, the savings do not reduce either the grants or the property taxes; it simply allows the Board to spend more on other goods and services, which is to say that there is no clear incentive to either the province or the taxpayer to proceed with conversion.

All new schools require the approval of the province's Architectural Services group which determines the capital cost grant for the school board based on the number of students and classrooms. All other space, e.g. offices, corridors, storage rooms, and maintenance buildings, is not eligible for a grant. Therefore, if a Board considers chip combustion for a school, with its associated higher capital cost, it must find additional funds somewhere, such as by sacrificing some of the non-eligible space previously listed. This most Boards hesitate to do.

There is simply no requirement in the system to calculate, and be guided by, long-term heating costs. This statement applies to all government buildings, not just schools. Naturally both capital cost and anticipated maintenance costs must be considered, and the latter are not well documented at this time. Undoubtedly there will be some cases, particularly those involving small buildings, or where low-cost natural gas is available, where chip combustion is not economically justified; however, the choice of fuels should be made carefully. The economy of most of eastern Canada - excluding Montreal and Southwestern Ontario - would be changed considerably if three simple questions were asked concerning the heating system of all proposed new public buildings:

1. Energy, Mines & Resources Canada. 1984. National Study of the Viability of Using Wood for Domestic Heating. p. 232B. CANMET, Office of Technological Information, 580 Booth St., Ottawa, Ont. K1A 0E4.

2. Energy, Mines and Resources Canada. 1991. Performance Testing of the 90 kW Bioblast Wood Chip Combustion Unit.

3. Energy, Mines and Resources Canada. 1991. Canadian Energy Statistics.

4. Etkind, Norman; Hudson, Norman and Slote, Stuart. 1989. How and Why Three Vermont Public Schools Converted to Wood Chip Fired Heating Systems. Vermont Public Service Department, Montpelier, Vt. 05602.

S. Folkema, Michael. 1989. Handbook for Small-to-Medium Size Fuelwood Chipping Operations. p.16. Forest Engineering Research Institute of Canada, 143 Place Frontenac, Pointe Claire, Quebec H9R 4Z7.

6. Folkema, Michael. 1993. Economics of Chipping Logging Residues at Roadside. Forest Engineering Research Institute of Canada. (in press).

7. Honer, T.G., Clark, W.R., and Gray, S.L. 1990. Determining Canada's Forest Area and Wood Volume Balance, 1977-1986. Forestry Canada. Place Vincent Massey, 351 St-Joseph Blvd., Hull, Quo. K1A 1G5.

8. McCallum, B. 1990. General Performance Monitoring of Four Small-Commercial Woodchip Combustion Systems in PEI. Energy, Mines and Resources Canada.

9. McCallum, B. 1992. Handbook for Small Commercial Biomass Systems on PEI. Energy, Mines and Resources Canada.

10. Morris, D.E. 1991. The Wood-Fired Electricity Industry in New Hampshire. Dept. Resource Economics, U. of N.H., 325 James Hall, Durham, NH 03824.

11. National Energy Board, 1990. Annual Report, p. 8, plus NEB data for 1970 and 1980. Also, 1991 Supplement to Annual Report, p.6.311 6th Ave. SW, Calgary, Alberta, T2P 3H2

12. Now England Governors Conference, Inc. 1988. Biomass Compendium. 76 Summer St., Boston, Mass. 02110.

13. Statistics Canada. 1990. #65202 Exports, Merchandise Trade; and #65203 Imports, Merchandise Trade. Tunney's Pasture, Ottawa. K1A 0T6.

14. Tennessee Valley Authority. 1990. Economic Impact of Industrial Wood Energy Use in the Southeast Region of the U.S., General Synopsis. Biotechnical Research Dept., Muscle Shoals, AL 35660.

Braaten, R.W., and Sellers, T.G. 1993. Prince Edward Island Woodchip-Fired Boiler Performance. Energy, Mines and Resources Canada., Combustion and Carbonization Research Laboratory, Ottawa, Ont., K1A 0G1.

Chamberlin, R. and High, C. 1986. Economic Impacts of Wood Energy in the Northeast. Resource Policy Centre, Thayer School of Engineering, Dartmouth College, Hanover, N.H.

Energy, Mines and Resources Canada. 1987. Small-Commercial Woodchip Combustion Technology Workshop, Charlottetown, PEI.

Energy, Mines and Resources Canada. 1988. Minutes of Chip Combustion Workshop, Rockland, Ont.

Gulland, J. and Theilheimer, 1. 1992. Industrial-Strength Wood Energy. Newviews Community Forestry Inc., P.O. Box 1000, Killaloe, Ont. K0J 2A0.

LeMay, C. and O'Connor, G. 1988. Design and Performance of Wood-Chip-Fired Stokers and Preheaters (Output Range 25 to 75 kW), Final Report. Energy, Mines and Resources Canada.

Owens, E.T. ed. 1988. Wood Energy Symposium Proceedings. Now Brunswick Department of Natural Resources, P.O. Box 6000, Fredericton, N.B., E3B 5H1.

The following conversions are only estimates; the actual figure varies according to species, moisture content, diameter, straightness of the logs, etc.

Ovendry wood fibre has an energy content of approximately 20.30 MJ/kg (8600 BTU/lb.). This is known as the Higher Heating Value (HHV). Green wood has a lower energy content per unit weight because some of the weight is water, e.g. the HHV of wood at 50% MCwb is 10.15 MJ/kg (4300 BTU/lb.), and the HHV of wood at 40% MCwb is 12.18 MJ/ kg (5160 BTU/lb.). The amount of heat delivered per unit weight is lower still: some energy is required to evaporate the moisture from the wood; there are efficiency losses in the combustion process, and jacket losses if heat radiated from the jacket is not utilized. The evaporation loss is equal to 2.442 MJ/kg of water (1050 BTU/lb. Heat yield per pound of ovendry fibre varies slightly according to the species, e.g. 8836 BTU for pine; 8640 for poplar; and 8448 for hickory.

A decrease in chip MC from 50% to 40% automatically affects the "overall efficiency"8 of the appliance because the heat loss due to evaporation is decreased. Since every appliance is designed for a particular MC range, and efficiency decreases as chip MC deviates beyond this range, the effect of a MC change on efficiency depends on whether the new MC is closer or further from the design MC. If the appliance is designed for 40% MC, it is probable that, at a burn rate corresponding to 70 percent of rated capacity, the combustion efficiency would increase by 5 percentage points, e.g. from 60% to 65%. This means that the amount of heat delivered per unit weight of chips, aside from jacket losses, would be:

On the other hand, if the appliance is designed for 50%MC chips, it may not burn well with 40% MC chips, and efficiency could very easily remain at 60%

Apart from all other factors, including a change in "combustion efficiency", the change in MC would have this effect on head generated:

Because the effect of MC change on combustion characteristics may be unknown, calculations of this type are a bit academic however, the potential gain due to chip drying is quite largo, and a thorough research project is warranted. Some studies have been conducted on drying small volumes of chips (e.g. a year's supply for a home) but the data are fragmented and should be consolidated. Some small-commercial storage facilities have provision for inducing a slight draft of air either upwards or downwards through the pile. In a recent Minnesota study 9 tree-lengths were stacked 100 feet high using a tower crane; there was no stability problem. The sides were wrapped with tarpaulins and 130ºF air (waste flue gas) was introduced below the tree lengths. In 30 days MCwb was reduced from 44% to 20%, i.e. 700 tons of water were removed and heat yield from the chipped material was increased by 65%* Some installations operate successfully on dry furniture plant residue. An alternative approach to drying chips is to burn chips at 50% MC, condense the flue gases, and recover heat.

In Systeme International (SI) notation, the unit of energy is the joule, a force of one newton acting through a distance of one metre. Power is the measure of how fast energy is delivered or used. One watt is the delivery of one joule of energy per second.

When power is generated at a constant rate, the amount of energy produced in a given time is: energy = power x time, consequently 1 joule = 1 watt-second. A joule is a relatively small amount of energy. For convenience in expressing large quantities, prefixes are used to form multiples of the joule:

To recapitulate, 1 tonne of chips at 40% MCwb, burned with 65% efficiency, provides 7920 MJ of delivered heat, the same amount of heat provided by 256 L (1.61 barrels) of #2 oil burned with 80% efficiency. Therefore, in terms of fuel cost per unit of delivered head, oil at 26 cents/L is equivalent to 40% MC chips at $66.56/tonne, without considering the additional social benefits provided by chips.

If the average efficiency is 70 percent (because the chips are at 35% MCwb, and the combustor is seldom reduced to a low burn rate), then one green tonne chips would provide 9236 MJ of delivered heat, the same amount of heat provided by 299 L (1.88 barrels) of #2 oil burned at 80% efficiency, i.e. the equivalent chip cost would be $77.74/tonne.

Refers to a plant designed to produce both electrical energy and thermal energy. Typically, high pressure steam from the wood-fired boiler passes through steam turbines to generate electricity, and then the low pressure steam is used to provide process heat.

Overall efficiency - in North America this term refers to the delivered heat divided by the heat potential of the fuel input assuming that it is ovendry. The delivered heat is less than the potential of the input due to three types of loss: (a) some of the energy in the wood is required to evaporate the moisture in the wood before it can burn; (b) some of the carbon does not react; i.e. it goes up the chimney; and (c) the radiated heat loss from the jacket of the appliance. If the combustor is located in a building which must be heated, then the jacket loss can be disregarded. Where heat is transported to another building through insulated pipes, there is also a transport loss.

Combustion efficiency

Refers only to the carbon reaction, and is seldom used.

Stoker

An automatic fuel feeding device connected to an appliance.

Types of Combustion Equipment

Three types of chip-fired combustion equipment are briefly discussed in this report:

The moisture content of wood, as a percentage, may be expressed in two ways.

MCwb means "moisture content, wet basis", and is calculated as: (weight of water x 100) divided by (weight of water + wood)

MCdb means *moisture content, dry basis", and is calculated as: (weight of water x 100) divided by (weight of wood)

In both cases the "weight of water" is equal to the wet weight of the wood minus the dry weight. The "weight of wood" is the final weight after a wood specimen has been dried in an oven at 103ºC until no further weight loss occurs. MCdb is used primarily to describe the MC of lumber; in wood combustion (and in the pulp and paper industry) only MCwb is used.

Canadian Manufacturers of Appliances Designed for Chip Combustion

M.r V. Court Grove Wood Heat Inc. Little York, P.E.I. C0A 1P0 (902) 672-2090 Mr. M. Frey Maco Enterprises R.R. 2, Drayton, Ontario N0G 1P0 (519) 638-2746 Mr. T. Gunnel Sylva Energy Systems Inc. 519 Richard St., Thunder Bay, Ontario P7A 1R2 (807) 683-6795 Mr. B. Rosen KMW Energy Systems 150 White Oak Road, London, Ontario N6E 3A1 (519) 686-1771Grove Wood Heat Inc.