After several years of research, switchgrass has proven to be the most promising crop for energy and fibre applications in eastern Ontario and southwestern Quebec. Switchgrass is also the subject of a substantial development effort in the United States, where the crop has been identified in the early 1990’s as a model herbaceous energy crop species by the Department of Energy. More recently, a switchgrass research network involving five countries has been established in the European Community. Several market opportunities involving switchgrass will be available to eastern Ontario farmers in the upcoming years. This management guide intends to provide the basic knowledge on how to successfully grow switchgrass.

Switchgrass (Panicum virgatum L.) is a native, perennial warm season grass. It is one of the three major native grasses found in the North American tallgrass prairie prior to settlement. Switchgrass is currently grown in the United States as a mid-summer forage crop, especially in the southern states, and for erosion control purposes in the Midwest, primarily under the Conservation Reserve Program (CRP).

As a warm season grass, switchgrass produces most of its biomass from June to August. Warm season grasses include crops such as corn, sorghum and sugarcane. The successful production of switchgrass requires different production techniques and harvest schedules than those used for cool season grasses such as timothy, alfalfa, and reed canarygrass. In particular, switchgrass is slow to establish. A stand which appears poor in the seedling year often produces a high yielding stand in subsequent years.

Switchgrass varieties are classified into two broad categories: lowland and upland. Lowland varieties historically developed under floodplain conditions, while upland varieties developed under drier upland sites. Yields up to 26 tonnes per hectare (10.5 tonnes/acre) have been achieved with some lowland varieties in research trials in Alabama, which is nearly twice as much as what is generally obtained with upland varieties. Unfortunately, lowland varieties have shown to be more susceptible to winterkill and are thus not reliable for production in eastern Ontario. Upland varieties will provide eastern Ontario farmers with the best productivity, at a minimum risk.

Cave-in-Rock is the most widely recommended variety for northeastern North America’s climatic and soil conditions. In small commercial-size sites in Quebec, Cave-in-Rock was the most productive of three varieties examined (Table 1), although all three varieties are recommended for production in eastern Ontario. New switchgrass varieties with improved seedling vigor and yield are currently under development by US and Canadian plant breeders.

|

Table 1: Switchgrass Fall Yields from Small Commercial-Size Sites, Ste. Anne de Bellevue, Qc 1994-1998 Tonnes of dry matter per ha | ||||||

|

Variety |

‘94 |

‘95 |

‘96 |

‘97 |

‘98 |

Average |

|

"Less fertile" site | ||||||

|

Cave-in-Rock |

9.7 |

11.0 |

11.9 |

11.7 |

13.7 |

11.6 |

|

Pathfinder |

9.9 |

10.9 |

11.3 |

11.6 |

13.2 |

11.4 |

|

Sunburst |

8.8 |

9.5 |

10.9 |

12.0 |

11.9 |

10.6 |

|

"More fertile" site | ||||||

|

Cave-in-Rock |

7.9 |

9.6 |

12.7 |

13.5 |

11.3 |

11.0 |

|

Pathfinder |

7.4 |

9.7 |

11.3 |

12.8 |

12.2 |

10.7 |

|

Sunburst |

7.0 |

8.5 |

10.1 |

12.4 |

10.0 |

9.6 |

Switchgrass is grown as a one-cut crop per year, with the harvest performed anywhere from late April to the end of May. One cut annually is the most cost-efficient option. Delaying the harvest to the following spring has the advantage of improving winter survival and weed control, reducing fertilizer requirements for the following growing season, and improving the combustion and papermaking properties of the material. In addition, the cold and dry winters experienced in eastern Ontario reduce the moisture content of the crop from 30%-40% in the late fall to below 15% in the spring, which can eliminate the need for field drying, prior to baling.

No precise guidelines are available for eastern Ontario farmers who would like to harvest switchgrass in the fall instead of in the spring. In the Midwestern United States (e.g. Iowa), longer growing seasons are experienced than in eastern Ontario, therefore recommendations are to initiate harvesting two to three weeks after a killing frost. Switchgrass becomes dormant after a killing frost and harvesting does not damage the stand as long as the plants have had sufficient time to translocate part of their nutrients to their root system, for use in the upcoming growing season. Given the poor field drying conditions prevailing during the fall in eastern Ontario, delaying harvest two or three weeks after a killing frost is not realistic in most years. Farmers who wish to fall harvest in eastern Ontario are advised to select early maturing varieties and cut at 15-20 cm stubble height, after leaf yellowing. Alternating stand harvest between spring and fall may also help to maintain stand productivity.

Eight to 10 kilograms of Pure Live Seed (PLS) per hectare are recommended for a successful establishment. Switchgrass is usually sold based on its PLS content as the seed varies greatly in purity and germination. Seed lots with equal amounts of PLS may differ in their volume of bulk seed. This must be taken into consideration when calibrating seeding equipment.

Newly harvested switchgrass seed can have a high percent dormancy. Acceptable germination levels are often achieved after one year of storage. For newly harvested seed, a dormancy rating of 10 percent or less is excellent. Seed cost currently varies between $8-$20/kg, depending on the desired variety and demand.

Research to date in eastern Canada and in the United States indicates that switchgrass is easier to establish on loam and sandy soils than on clay soils. Switchgrass seed is fairly small, therefore poor contact with the seedbed caused by clay clumps will delay, or result in poor, germination. Clay soils are also usually slower to warm up in the spring. Packing right before and after planting is highly recommended on all soil types, especially on clay soils. A good rule of thumb for seeding is that a footprint should barely be visible in the soil before seeding.

Switchgrass will perform best on well-drained soils (surface and/or tile drainage), however research is still required to define the minimum level of drainage required. Due to the extensive root system and perennial nature of switchgrass, high productivity on medium to lower fertility soils is easier than with most annual crops. Soil pH should be 6.5 or higher.

As switchgrass is fairly slow to form a canopy, weed control is critical to achieving a successful establishment. In the fall preceding establishment, the fields can be sprayed with a broad-spectrum herbicide to eliminate problem perennial weeds, such as quackgrass, from invading the establishing stand. Summer or fall tillage is recommended for forage and pasture fields in order to break sod clumps.

In the spring, seeding should be performed when soils are relatively warm. Seeding usually takes place between May 15th and June 10th. Soil preparation should include one or two passes of harrow (or disk) and packing (cultipacking). An additional tillage operation may be performed in early May to promote annual weed growth. Seeding can be performed using a regular cereal drill equipped with a forage seed box, or using forage planters, at a seeding depth of 0.5-1.0 cm (1/4 to 1/2 inch). The fields should be packed directly after seeding. On light soils, no-till establishment is another possibility. This has not been tested in eastern Canada but is practiced in the United States.

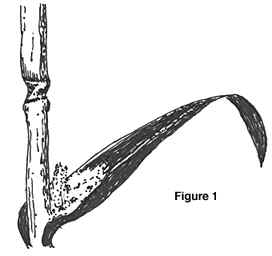

Switchgrass seedlings can be difficult to distinguish from grass weeds, especially foxtail. A key feature of switchgrass plants is the white patch of straight hair at the point where the leaf (topside) attaches to the stem (Figure 1). The stem is round and usually has a reddish tint. A stand is successfully established if 10-32 seedlings per m2 (1-3 seedlings per ft2) can be found at the end of the establishment year.

No herbicides are registered for use on switchgrass in Canada. The recommendations that follow are based on research trials in Canada and in the United States. It is the farmer’s responsibility to read and comply with the label instructions of each product. A first rule of thumb would be to avoid using hormone herbicides, such as 2,4-D, which are known to reduce switchgrass development in the seeding year. Switchgrass seedlings and mature plants show tolerance to atrazine. Guidelines from the United States are to use Aatrex atrazine at 1.1-2.2 kg/ha of active ingredient (1-2 lbs./acre) at, or soon after, planting. Basagranâ (bentazon) and Laddockâ (blend of atrazine and bentazon) are effective against post-emergent broadleaf weeds, with minimal crop damage.

Grass weeds are the most difficult to control in a switchgrass stand, as it is difficult to find herbicides that select grass weeds from switchgrass seedlings. Research is ongoing on this issue and guidelines should be available within the next few years.

In the event of weed invasions in switchgrass stands, a possible weed control strategy involves clipping the weeds just above the switchgrass canopy. Clipping can be performed several times during the growing season if necessary. The main disadvantage of this strategy is the potential to remove growing switchgrass, which may delay switchgrass establishment.

In most cases, nitrogen fertilization is not required in the establishment year, as the crop is an excellent nutrient scavenger, and applying nitrogen fertilizer can stimulate weed growth. Potassium and phosphorus fertilizers are not applied during establishment, unless levels are low (less than 81 ppm for potassium, and less than 10 ppm for phosphorus, according to OMAFRA guidelines for forage crops). Switchgrass seldomly responds to potassium and phosphorus fertilizer as it has a large root system and relies on mycorrhizae for phosphorus uptake.

To ensure a vigorous regrowth in the second season, it is highly recommended that the switchgrass grown in the establishment year be overwintered and harvested only during the following spring.

Research conducted in eastern Canada indicates that maximum production is attained during the third growing season. The first crop (establishment) will produce 30%-40% of the maximum potential production, and 70%-80% in the second growing season. Once established, a switchgrass stand may last 10 years or more.

The most reliable harvest strategy to date is to spring harvest. Switchgrass initiates growth only at the end of May to early June, which leaves about 6 weeks to harvest prior to new growth. The standing material is fairly dry during that period. To avoid shattering and loss of material, the use of a conditioner is not recommended. Swathers can be used to gently mow crops. For industrial markets, such as pulp and paper and ethanol, the use of large square bales is recommended.

In most cases, the only operation required following harvesting is the application of nitrogen fertilizer. For a spring harvest regime, 50-60 kg of actual nitrogen per hectare every year (45-53 lbs./acre) is sufficient to sustain production. Switchgrass fields in eastern Canada have usually been fertilized using ammonium nitrate. Over-fertilization with nitrogen usually results in crop lodging, which ultimately results in yield reduction and harvesting difficulties.

By adopting a spring harvesting regime, phosphorus and potassium fertilization are usually not required on medium to rich soils. Soil concentrations of these two nutrients should be monitored 2-3 years after establishment and fertilization performed if deemed necessary.

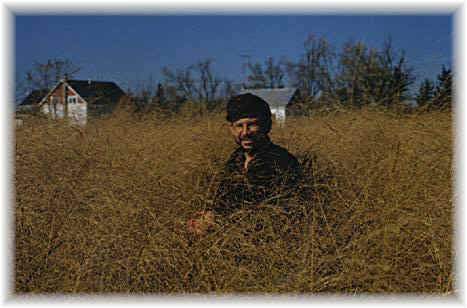

Switchgrass can produce 8-13 metric tonnes (dry matter) per hectare in eastern Ontario once it is fully established (3.2-5.3 tonnes/acre). Leaving the crop in the field over winter will reduce harvestable yield in the following spring by 25%-30%, primarily due to the loss of seed heads and leaves. However, the resulting material will have an improved quality for papermaking and combustion applications. Research is ongoing to improve the yield and quality of switchgrass varieties available to farmers.

The perennial nature of switchgrass, along with its low input requirements and high productivity, are the main factors contributing to its low cost of production compared to most traditional crops. Research indicates that at $50 per dry tonne, the crop is profitable for eastern Ontario farmers. Across North America, this value is estimated to vary between $45 to $75 per dry tonne (this includes delivery costs), depending on yields achieved and the type of land used (idle or low quality land versus prime quality land).

Approximately 50% of the costs incurred in growing switchgrass are related to harvesting and transporting the crop to a conversion plant. Any efficiency gains made in these two areas will strongly influence returns to farmers. Other costs include the annual fertilization charges of approximately $50-$60/ha, and the amortization, usually over 10 years, of the establishment costs incurred in the first year.

Switchgrass is being developed primarily as a crop tailored to the energy and fibre markets. The crop has been identified as a close substitute to hardwood fibre for papermaking applications. With several papermills located in or around eastern Ontario, business opportunities will develop in the future. Ethanol, an alternative fuel currently produced from grains, will eventually be produced from forage crops and wood, i.e. from cellulose. The first demonstration plant in the world to manufacture ethanol from these feedstocks will be built in Ottawa by the turn of this century.

Residential heating is another potential energy application for switchgrass. Wood pellet stoves are increasingly popular while wood residues, the current feedstock, are becoming increasingly expensive. A recent breakthrough in pelletstove combustion design, by the Canadian firm DellPoint, now enables feedstocks higher in ash content, such as switchgrass, to be burned efficiently. Pelletizing of switchgrass is currently being optimized.

Other markets include using switchgrass as animal bedding (a substitute to cereal straw), or as a potential fibre feedstock in construction material manufacturing.

Greenhouse gases, such as carbon dioxide, contribute to increases in the earth’s temperature by forming an insulating layer in the atmosphere, similar to a greenhouse effect. Canada has agreed to reduce its emissions of greenhouse gases by 6% under 1990 levels by the year 2012. Switchgrass can help Canada to meet this commitment by producing biofuels (ethanol, pellets) to replace fossil fuels; the main sources of greenhouse gases.

Switchgrass could also reduce greenhouse gas emissions by increasing soil organic matter where it is grown. Organic matter is formed by the accumulation of plant residues (straw, roots) in soils; plant residues that used carbon dioxide in their formation. The potential of switchgrass to sequester carbon as organic matter in soils under eastern Ontario conditions is being quantified.

Updated editions of this management guide will be available. In the meantime, additional information can be obtained by contacting:

This management guide was made possible with support from the Ontario CanAdapt program, managed by the Agricultural Adaptation Council: 90 Woodlawn Road West, Guelph, Ont., N1H 1B2, Tel: (519) 822-7554; Fax: (519) 766-9775, E-mail: canadapt@adaptcouncil.org, Web: http://www.adaptcouncil.org/.

The authors would also like to thank Natural Resources Canada for their ongoing support in developing switchgrass as an industrial crop.