A Process and Energy Analysis of Pelletizing Switchgrass

Final Report

Prepared for:

Natural Resources Canada,

Alternative Energy Division

Prepared by:

R Jannasch, Y. Quan, and R. Samson

Resource Efficient Agricultural Production (REAP-Canada)

P.O. Box 125, Ste. Anne de Bellevue, QC H9X-3V9

www.reap-canada.com

Executive Summary

A commercial scale pelleting trial using switchgrass feedstock was conducted in Ste. Marthe, Quebec, in August, 2001, to study the pellet production process at a commercial alfalfa dehydrating plant and assess energy use, percent yield and quality of the finished product. Nine tonnes of baled switchgrass (14.5% moisture) were pelleted.

Square bales were easier to process than round bales and baled switchgrass could be broken and course chopped in 30% less time than alfalfa. The crop could be pelleted without drying which generated a cost saving over sawdust and alfalfa of $8-12 per tonne. A reduction in screen size from 1/8 inch to 7/64 inch for the fine grinding process appeared to produce a modest increase in pellet hardness. Pellet throughput was approximately 2 tonnes/h (20-22 lbs/HP), a rate similar to wood. Pellets hardness was similar to alfalfa and wood pellets, but less than optimum binding characteristics resulted in greater fine production during pelleting and handling. The loss of fines during the pelleting, cooling and temporary storage stages produced a percent yield of 91% on a dry matter basis. The percent yield of finished pellets was 57% of the initial feedstock supply; however, fines produced during the screening and shaking process were not re-pelleted. The binding quality of the feedstock and pellet durability could be improved by changes to the die configuration, steam treatment or natural additives. If the majority of fines were reprocessed in the pelleter it is expected that the yield of finished product would be increased to 95% of the original feedstock. The energy requirement for pelleting switchgrass is estimated to be 0.416 GJ/tonne. It is expected that energy efficiency could be increased substantially with the adoption of modern equipment in demonstration projects or by working with large-scale western Canadian pellet processors. Switchgrass appears to lack natural binding properties compared to alfalfa, and improving pellet durability is a major research and development priority for successful commercialization.

Introduction

After laboratory trials to pellet switchgrass for biofuel applications, REAP-Canada conducted the first commercial scale production of switchgrass fuel pellets in Ste. Marthe, Quebec, in December, 2000. This trial attracted considerable interest from farmers, wood pellet producers, pellet distributors and domestic users from across Canada, the United States and Europe. The recent endorsement of the Kyoto Accord to reduce greenhouse gas emissions, as well as recent fluctuations in energy prices and questions surrounding the security of domestic energy supplies has heightened interest in grass biofuel pellet production.

Information about production processes and costs of commercial-scale pellet production is limited. Previous data collected by REAP-Canada was from laboratory-scale experiments using a 2 HP lab bench pelleter and a 25 HP California Pellet Mill (Samson and Duxbury, 2000). King (1999) proposed detailed estimates on throughput and energy use for a commercial plant, but the data was not based on in situ -trials. A process analysis for a larger scale switchgrass pelleting facility is necessary to describe and evaluate the pelleting process, assess energy use and make preliminary production data available to industry. Results from the December 2000 trial suggest modifications to the pelleting process are required to improve pellet durability. This report will describe the pelleting process for switchgrass during a commercial-scale pellet run conducted in August, 2001, with the goal of establishing baseline production data and identifying further research needs.

Methods

The switchgrass pelleting trial was conducted at a commercial alfalfa pellet mill, Les Luzernieres Belcan, in Ste. Marthe, Quebec, on August 24, 2001. Belcan is a family owned mill which has produced alfalfa and wood pellets since 1958. A previous switchgrass pellet run was conducted at the plant in December, 2000. This company produces about 10,000 tonnes of alfalfa pellets during a 4-5 month season. Wood pellets are processed when feedstock is available.

Thirty-four round bales (4 ft) of spring harvested switchgrass (stored on asphalt under tarpaulins) were used in the study. Average bale weight was 269 kg (593 lb) for a total lot weight 9146 kg (14.5% DM). The total dry matter available for processing was 7.8 tonnes. REAP researchers worked together with plant owner and operator, Ives Trottier, to conduct the trial. Two representatives from Shaw Resources, a Nova Scotia company producing wood pellets, also requested to be present during the pellet run (the supply of wood fibre residues is diminishing in their region). REAP-Canada requested that they provide an assessment of the commercial feasibility of switchgrass pelleting.

The scope of the study was limited by a number of factors. It was conducted during the busy alfalfa season and time constraints prevented focusing operations at the plant on a dedicated study of switchgrass pelleting. A series of adjustments were made to the processing equipment (dryer, fine grinder, pelleter) to assess the effects on throughput rates (tonne/h), energy use (KW/tonne), pellet quality, fine production and the moisture content, bulk density and percent yield of finished pellets. However, a shortage of storage space made it impossible to separate the pellets into separate lots. Antiquated and limited equipment at the plant prevented a complete analysis of all processes. Data from processing round and square alfalfa bales (second cut) with a moisture content of 17.7% and 16.7% were collected on August 31, 2001. The dryer was operating at 105 ° C.

Figure 1. The Belcan dehydrating plant, Ste. Marthe, Quebec.

Results and Discussion

The Pelleting Process

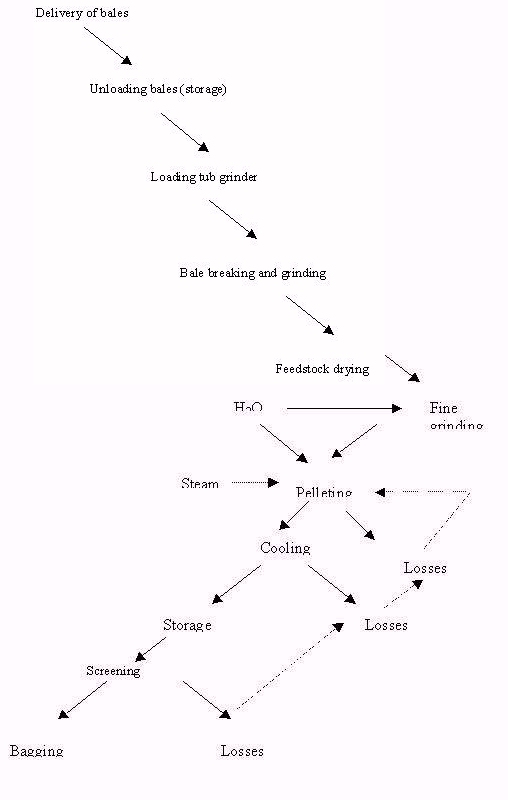

The entire production process from bale delivery to bagging pellets is outlined in Fig. 2.

Figure 2. Flowchart describing the Belcan switchgrass pelleting operation

Bale delivery

Bales are delivered by semi-trailer truck or tractor to the plant. Large square bales weighing approximately 750 lb (340 kg) are preferred over round bales due to their greater density, ease and efficiency of transport and lower breaking costs. Round bales are still used in many agricultural regions, but there is a gradual shift towards large square bales. Some alfalfa dehydrating plants handle only bulk forage if an adequate feedstock supply can be obtained near the plant. This method avoids baling and bale breaking costs. In Denmark, self-propelled chaff cutters are sometimes used to blow straw into wagons in bulk for transport to storage (CBT, 1998).

Storage

Depending on the size of the pelleting facility, bales may be unloaded directly on an asphalt pad for immediate processing (within 1-5 days), or storage may be required for larger plants. The storage capacity will depend on the plant’s output and whether it operates year round. Mr. Trottier stated that harvest and storage methods must ensure a consistent moisture level in switchgrass bales otherwise the efficiency of the drying, grinding and pelleting process can be adversely affected. In particular, he was concerned about the ability to produce uniform pellets from damp material (e.g. wet sections where bales touch each other or the ground).

Bale breaking and chopping

At the Belcan plant a 200 HP tub grinder (WHO Manufacturing, Nebraska) is used to break bales and chop forage fibres to a length suitable for drying (2.5-10 cm).Tub grinders are normally used for processing livestock feed such as hay. Course chopping is not necessary when pelleting wood residues such as sawdust. Bale type affects feedstock throughput. More time is required to process large round bales than square bales. Round bales have full length, wrapped fibres whereas fibres in square bales are shorter and the bales tend to fall apart in flakes. Some commercial alfalfa dehydrators in western Canada increase breaking rates by cutting round bales in half with over-sized chain saws before placing them in a tub grinder. Square and round bales are often mixed at the Belcan plant to optimize throughput.

Feedstock Drying

A dryer is normally used to reduce feedstock moisture to levels suitable for pelleting. Moisture levels in wilted alfalfa and sawdust commonly range from 35-70% whereas baled alfalfa and switchgrass usually contain between 12-20% moisture. Feedstock at the Belcan plant is dried to between 10-12% before fine grinding using a rolling drum dryer fueled by natural gas. Some commercial wood pellet mills use wood waste as a fuel source to reduce expenditures for natural gas.

Fine grinding (hammer mill)

A hammer mill is used to reduce the size of feedstock particles in preparation for pelleting. The fineness of grind can be adjusted by the screen size. Belcan normally operates with a 1/8 inch screen for alfalfa, and the same screen size was used during REAP’s initial pellet run in November, 2000. Smaller screens are thought to decrease particle size and increase the binding properties of the feedstock (Dobie, 1959). A 1/4 or 5/16 inch screen is normally used for producing wood pellets (Leaver, 2001). A high temperature steam, vegetable oil or water spray can be applied during the hammer milling process to improve feedstock binding quality and throughput. The results of this study focus on pellets made with a 7/64 screen using a 150 HP Champion hammer mill (Table 1).

Pelleting

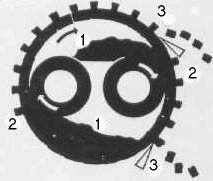

Chopped feedstock is fed into a pelleting chamber where rollers force the ground feedstock through holes on the inside face of a die. As pellets are extruded, adjustable knives cut the pellets off to the desired length on the outside of the die (Figure 3). Successful pelleting depends on a number of factors including the moisture content of the feedstock, feedstock density, particle size, fibre strength, the feedstock’s lubricating characteristics and the presence of natural binders (Assessment of pelletized biofuels; www.reap-canada.com). High temperature steam is sometimes used in pelleting operations to activate natural binders and lubricants in biomass feedstocks, but the Belcan boiler was not operational at the time of the study. Water can also be added during the pelleting stage for a similar but less pronounced effect.

A typical die for alfalfa pellets has a 1/4 inch diameter and 2 inch effective thickness whereas a die for wood pellets would be 1/4 inch in diameter with a 1.5 inch effective thickness (Michel Viau, personal communication). A 200 HP Sprout Waldrin pellet mill using a ¼ inch diameter Sprout die with 2 inch effective thickness (no release) was used for the current trial.

Cooling

Pellets exit from the pelleter at high temperature and are cooled with forced air to prevent "sweating". Small quantities of fines (material broken off during the pelleting and handling process) can occur at the exit point of the cooler. Normally this material is collected by a conveyor and repelleted.

Storage

Pellets are normally moved to a temporary storage area after cooling by conveyors or augers. Bulk grain storage tanks are usually used.

Figure 2. Diagram of Pelleting Process: (1) Loose material is fed into pelleting cavity. (2) Rotation of die and roller pressure forces material through die, compressing it into pellet. (3) Adjustable knives cut pellets to desired lengths.

Screening

A screening process is used to separate fines from the finished pellets before bagging. This step is essential for producing high quality, user-friendly pellets. Fines can be redirected to the pelleter by conveyor or auger for reprocessing.

Bagging

The final step in the production process is bagging. In North America, the majority of wood pellets are packaged in 18 kg (40 lb) bags and sold from the plant on shrink-wrapped skids. The development of large, district wood pellet heating systems and pellet furnaces in Europe has generated a demand for bulk fuel pellets sold in 1 tonne "tote" bags or delivered by pneumatic tanker trucks (Malisius et al. 2000). The installation of similar systems in North America could eliminate the need for bagging and considerably reduce production costs ($20-30/tonne).

Analysis of the Belcan pelleting system

Bale breaking and chopping

Switchgrass round bales were broken and chopped at a rate of 8 tonnes/h or approximately 25 HP/tonne processed. The grinder operated about 40 minutes per hour due to a higher output compared to the pelleter. The fibre length ranged from 2.5-10 cm. The estimated energy requirement was 14.9 KWh/tonne. The power requirement is similar to that of alfalfa, but Mr. Trottier believes the throughput is about 30% higher for switchgrass because the bales break apart more easily. Mr. Trottier estimated that for processing switchgrass it would be feasible to reduce the motor size to 150 HP and maintain the same throughput.

Further efficiency could be achieved by processing strictly square bales since these require about 20% less time for breaking and chopping compared to round bales. An industrial bale breaker from Newhouse Manufacturing in Oregon is capable of breaking and chopping large square straw bales to 3-15 cm lengths with an 80 HP motor at a rate of 10 tonne/h. This would generate a considerable energy saving over the equipment used in the current study.

Feedstock Drying

The dryer was initially set at 70° C with an ambient temperature of 80° C. The initial switchgrass pellets produced were very small and hard. Throughput was about 1.25 tonnes per hour. The dryer was shut down to prevent the loss of forage moisture. Pellet throughput increased and pellet size increased. Some drying still occurred while the feedstock passed through the systems as the feedstock moisture content dropped to approximately 8.5% before entering the pelleter (Table 2). It was clear that spring harvested switchgrass with a moisture content of 14.5 % or less can be pelleted without prior drying. Mr. Trottier estimated elimination of the drying step should generate cost savings over sawdust or alfalfa (from 18 to 11%) of between $8-12 per tonne depending on the price of gas (approximately 1.25 GJ per tonne). He estimates the cost of drying wilted alfalfa from 55 to 11% moisture at $45/tonne. Feedstock with a higher moisture content may require drying before pelleting.

Fine grinding

The Belcan operation normally uses a 1/8 inch screen in the hammer mill. In an attempt to increase pellet hardness and durability over the 2000 trial, the mesh size was reduced to 7/64. The resulting feedstock was visibly finer. However, there appeared to be no measurable changes to pellet size or throughput rates. A visual comparison made by Mr. Trottier and REAP staff, however, concluded that pellet hardness increased due to a greater proportion of pellets with an exterior sheen and fewer quantities of fines.

A short trial was conducted with a 7/32 inch screen to assess the effect of increasing grind size. Wood pellet manufacturers generally use a ¼ inch screen. Fibres were clearly longer, but the pellets were course and more fragile. The energy draw (amperage) of the hammer mill dropped from approximately 85 amps to 60 amps with the larger screen (Table 1).

Mr. Trottier explained that hammer mill output normally does not change significantly with different feedstock types or screen size. The 150 HP unit is capable of supplying the maximum output of the pelleter. There is a closed system between the hammer and pellet mill and it was not possible to conduct a precise assessment of throughput from the hammer mill in this experiment. Throughput was conservatively estimated at 2 tonne/h with an energy requirement of 55.5 KWh/tonne (Table 1). Energy use could probably be reduced by 50% if throughput were increased to 4 tonne/h, an output that would match the maximum output of the pellet mill.

|

Table 1. Energy use and throughput of fine grinding and pelleting processes | ||||||||

|

Run # |

Screen Size |

Hammer Mill Draw (amp) |

Fibre Through- put (tonne/h) |

KWh/ Tonne |

Pellet Mill Draw (amp) |

Pellet Through- put (tonne/h) |

KWh/ tonne |

lbs/HP |

|

1 |

7/64 |

60-70 |

2.0 |

55.9 |

100-125 |

1.25 |

119.3 |

11.3 |

|

2 |

7/64 |

85-95 |

2.0 |

55.9 |

140-160 |

2.0 |

74.5 |

22.0 |

|

3 |

7/32 |

55-60 |

2.0 |

55.9 |

140-160 |

2.0 |

74.5 |

22.0 |

|

4 |

7/64 |

85-90 |

2.0 |

55.9 |

130-155 |

2.0 |

74.5 |

22.0 |

|

5 |

7/64 |

72-80 |

2.0 |

55.9 |

125-135 |

2.0 |

74.5 |

22.0 |

1 kW = 1.3410 electric horse power (HP)

Pellet throughput and energy use

Total throughput averaged over five hours was 1.8 tonne/h (20-22 lbs/HP/h). This was similar to established wood pellet production rates (2 tonnes/h; 22lbs/HP/h) at the plant. Mr. Trottier believes 27.5 lbs/HP/h is achievable if a steam pre-treatment is used. Clean alfalfa has an average throughput of 3 tonne/h (33 lb/HP/h) and weedy alfalfa has a throughput more similar to switchgrass (25-28 lb/HP/h). Under exceptional conditions, throughput of second cut alfalfa may reach 4 tonne/h (44lb/HP/h), (Table 3). In larger, more modern Western Canadian alfalfa pellet plants, average season-long pellet production rates of 51 and 62 lb/HP/h are reported (Samson and Duxbury, 2000). Clearly, improvements are needed in both pre-treatment technologies and pelleting equipment if efficiency is to be increased. The current production rates at the Belcan mill indicate a relatively low productivity compared to the leading Canadian pellet companies.

|

Table 2. Switchgrass pellet characterisitics | ||||

|

Run # |

Feedstock Moisture (%) |

HotPellet Moisture (%) |

Cool Pellet Moisture (%) |

Bulk Density (lbs/ft3) |

|

1 |

7.9 |

6.1 |

4.5 |

- |

|

2 |

7.5 |

6.0 |

5.5 |

37 |

|

3 |

10.3 |

6.0 |

5.6 |

35 |

|

4 |

10.1 |

6.7 |

5.5 |

40 |

|

5 |

10.3 |

6.8 |

5.4 |

38 |

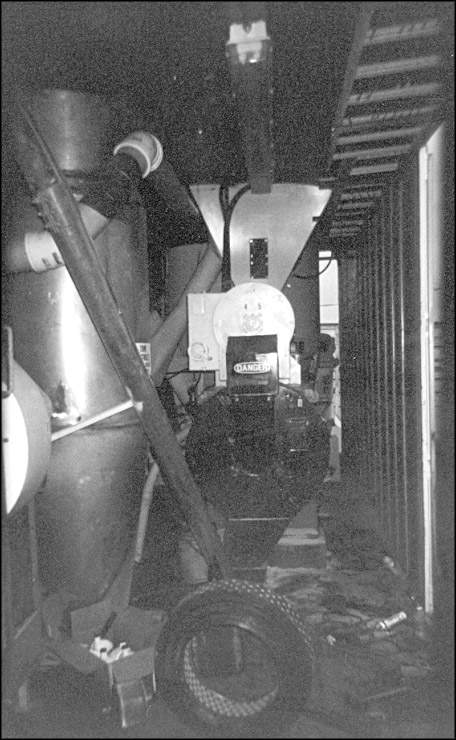

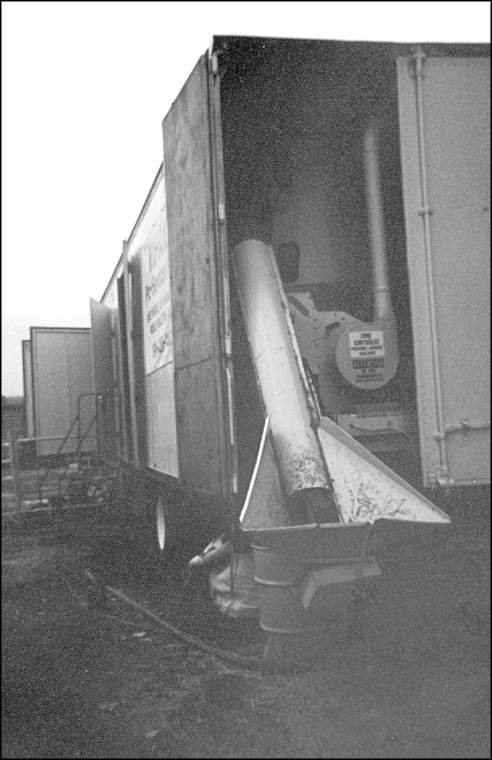

A previous estimate by REAP-Canada indicated rates of 45-70 lbs/HP/h (a range slightly below alfalfa) could be obtained if the processing steps were optimized and a modern facility was used (Samson and Duxbury, 2000). The development of the Ecotre pellet system in Italy (www.ecotresystem.com) may make these production rates feasible in the near future. For example, the Ecotre, 200 HP pelleter is reported to produce up to 4 tonnes of pellets per hour (44 lb/HP/h) from spruce sawdust with an electrical demand of 23 KWh/tonne. Another recent Canadian innovation is the development of a mobile pelleting system equipped with a 125 HP California Pellet Mill in a semi-trailer (Appendix 1). This prototype model is currently being tested and throughput is predicted at 2 tonnes/h. The energy efficiency has not yet been determined.

|

Table 3. Alfalfa pellet characteristics and energy use | ||||||||

|

Run # |

Feedstock Moisture (%) |

Hot Pellet Moisture (%) |

Cool Pellet Moisture (%) |

Bulk Density (lbs/ft3) |

Screen Size (mm) |

HM Draw (amp) |

PM Draw (amp) |

Pellet Through- put (tonne/h) |

|

1 |

9.6 |

8.5 |

9.0 |

35.0 |

1/8 |

70-90 |

150 |

4 |

|

2 |

9.6 |

8.5 |

9.6 |

34.5 |

1/8 |

70-90 |

150 |

4 |

At the Belcan plant, electricity use ranged from 119.1 KWh/tonne for dried feedstock to 74.5 KWh/tonne for undried switchgrass. King (1999) estimated 45 KWh for pelleting switchgrass whereas Tabil and Sokhansanj (1996) reported alfalfa pelleting required 30 KWh/tonne. The high energy requirement for this experiment was clearly affected by the low throughput of pellets. A doubling of pellet output to a range similar to alfalfa would improve energy use efficiency to values similar to those of alfalfa. Energy use by the pelleter did not appear affected by screen size of the hammer mill. The use of steam might decrease energy use further by increasing throughput.

At the optimum pelleting rate, fine production at the exit point of the pelleter was about 3%, but ranged as high as 25% depending on the amount of water added. In contrast, less than 1% fines were produced when pelleting alfalfa. Alfalfa fines are normally collected at the exit point of the cooler and returned to the pelleter. With the larger quantity of switchgrass fines, however, the old equipment at the plant did not have sufficient capacity to redirect the entire quantity of fines back to the pelleter.

Pellet Quality

The bulk density of switchgrass pellets ranged between 35-40 lbs/ft3 (Table 2). This value is similar to the density of pellets produced in the laboratory (38.5 lbs/ft3), (Samson and Duxbury, 2000). Actual pellet density in the current experiment may be at the lower end of this range because there was a considerable quantity of fines in the sample. Fines are normally removed before bagging. Density may also vary according to pellet length and diameter. Belcan alfalfa pellets have a bulk density of 35 lbs/ft3 (Table 3).

Glenn Hardie and Jeff McLellan from Shaw Resources do not foresee any major barriers to producing switchgrass pellets with good durability. In their opinion, the Belcan pelleting process needs only minor adjustments to produce good quality pellets without steam. "We don’t think steam would be an issue. From what we saw at Belcan, I can see making switchgrass pellets at our plant with no adjustments, but adding a tub grinder," said Hardie.

Options for improving pellet quality

The effect of water on the pelleting process

Water was added as a fine spray at either the fine grinding step or during the conditioning step before pelleting. Adding water has the effect of (1) improved feedstock binding properties, (2) increasing pellet size, (3) increasing throughput and (4) decreasing fine production. In general, water increased pellet size, reduced pellet hardness and increased throughput. The optimal quantity of water was 1.0 L per minute for an average feedstock flow of 2 t/h. Feedstock moisture prior to pelleting was approximately 10% (Table 2). Higher rates of 1.5 and 2 L/minute produced very large and soft pellets. When water was sprayed directly in the hammer mill, pellets became harder with an exterior sheen evident and fine production was lower. Presumably, water added at the conditioning stage prior to pelleting has less time to be imbibed in plant fibres. Water absorption may be improved by using food grade surfactants, soap or commercial wetting agents. Adding water increased pellet moisture at the exit point from the pelleter. However, during the cooling process, moisture is lost and final pellet moisture after cooling was unaffected by the addition of water to the pelleting process.

Fine production and percent yield of finished pellets

A total of 7.47 tonnes (7.1 tonnes DM) of unscreened switchgrass pellets were produced from 9.17 tonnes (7.8 tonnes DM) of raw feedstock. Loss of fines during the pelleting, cooling and temporary storage stages produced a percent yield of 91% on a dry matter basis. According to Mr. Trottier, a portion of the DM loss may have occurred at the exit of the drum dryer. Belcan normally expect a total DM loss of 4%.

The screening process produced additional fines, so that the final yield of bagged switchgrass pellets was 4.6 tonnes (4.3 tonne/DM), or about 57 % of the initial feedstock DM. Two factors were responsible for the relatively low final yield of pellets. The pellets were of marginal quality coming of the pellet line and the process of handling, screening and shaking produced large quantities of fines. Also, fines at the Belcan plant are normally returned to the pelleter. However, because bagging of the switchgrass pellets occurred several days after the pelleting trial, there was no opportunity to re-pellet the fines. Consequently, a large proportion of the original feedstock was lost. It is expected that under normal production conditions the percent yield could be increased to about 95% by increasing pellet hardness and using more modern processing systems. An anticipated 5% loss of DM is equivalent to most alfalfa pelleting systems.

Energy Use

Electricity use for course chopping, fine grinding and pelleting were 14.9, 55.9 and 74.5 KWh/tonne (wet basis), respectively. Assuming a throughput of 3.0 tonne/h for both the hammer and pellet mill, the total electricity demand would be 102 KWh or the equivalent of 0.342 GJ/tonne (on a DM basis). Estimated energy costs associated with conveyors, cooling fans, elevators and lighting are 0.046 GJ/tonne (Samson and Duxbury, 2000). The total energy requirement would therefore be 0.388 GJ/tonne. This value is somewhat higher than the 0.244 GJ/tonne estimated previously by REAP-Canada, in part because tub grinding (54 MJ/tonne) was not included in the study. The energy cost of pelleting at the Belcan plant (assuming a 3 tonne/h throughput) is almost double the estimated value used previously. More advanced technology such as the Ecotre pellet system which reportedly uses 23 KWh/tonne would have similar efficiency to that predicted in REAP’s previous study. It is clear that reducing the energy requirement for fine grinding and pelleting is critical to the efficient production of switchgrass pellet fuels. The most feasible means of reducing energy use is to improve equipment and pretreatment methods to increase throughput.

Conclusions

Drying spring harvested switchgrass before pelleting is not necessary provided bales are stored well. Square bales are easier to process than round bales. Switchgrass appears to lack natural binding properties compared to alfalfa and improving pellet durability is a major research and development priority for successful commercialization. Improving throughput and energy efficiency would best be accomplished using state of the art equipment in demonstration projects or by working with large scale western Canadian pellet processors. Further study to fine tune the switchgrass pelleting process is a matter of applying existing knowledge and is not expected to prevent commercial production.

Literature Cited

CBT (Centre for Biomass Technology) 1998. Straw for energy production: technology, environment, economy (2nd Edition). Danish Energy Agency, Copenhagan, Denmark.

Dobie, J.B. 1959. Engineering appraisal of hay pelleting. Agricultural Engineering, 40(2):76-72, 92.

King J.E. 1999. Pelletized switchgrass for space and water heating. Final Report, prepared by Coriolis Ltd., Lawrence, Kansas, (Jeking@idir.net) and submitted to the KCC, Grant no. DE-FG48-97R802102.

Leaver R.H. 2001. Wood pellet fuel and the residential market. Andritz, Inc. Sprout Matodor Division, 35 Sherman St. Muncy, PA 17756

Malisius (and others) 2000. Wood pellets in Europe. Industrial network on wood pellets. UMBERA, GmbH, A-3100 St. Poelten, Schiessenstattring 25.

Samson, R and Duxbury, P. 2000. Assessment of palletized biofuels. (www.reap.ca).

Tabil, L.G. and Sokhansanj, S. 1996. Process conditions affecting the physical quality of alfalfa pellets. American Society of Agricultural Engineers, 12(3):345-350.

APPENDIX 1

Appendix 2

Useful addresses:

Les Luzerniéres Belcan du Quebec Inc.

170, montée Ste. Marie

Ste. Marthe, Cté de Vaudreuil,

Quebec, J0P-1W0

Tel. 450-459-4546

Fax. 450-459-4366

E-mail : ytrottier@belcan.qc.ca

Ecotre System

Via delle Cantoine, 12 – 50040

Settimello (FI) Italy

Tel. 39 55 8827441

Fax 39 55 8827441

E-mail : ecotresystem@tiscalinet.it

VIFAM Pro-Services Inc.

125 Boulevard Kirkland, QC

H9J-1P1

Tel. 514-426-4482

Fax. 514-695-0408

E-mail : vifam@qc.aibn.com